|

|

Page 19 Spring 1991

|

Radtke

is no different from the other makers in jealously guarding his

ingredients and process. He said he uses the same

silicone material that forms artificial heart

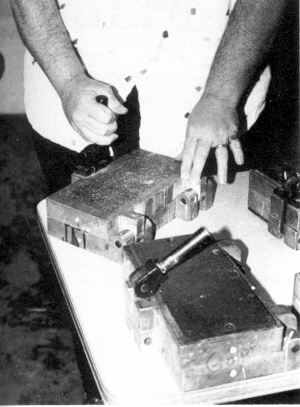

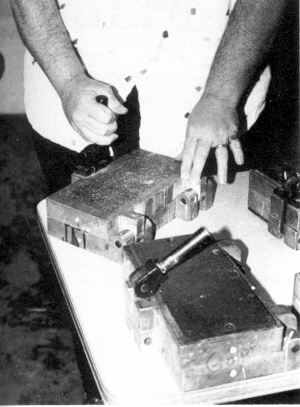

The

biggest challenge faced in the manufacturing process is to avoid air

bubbles. Radtke said he worked for two or three years to overcome

that problem. He's also proud that his balls have no visible "sprue"

or "vent" spots. They do have seams, though, because he

said, "you can't make

a ball without a seam."

Though

he runs a small shop, Radtke has some advantages that Dube and Smith

cannot match. First of all, he has molds to produce balls in nine

sizes, from 3/8" all the way to 3-1/16". He has also

devised a process to incorporate a juggler's initials, or other

design, permanently into the surface of the ball during its

manufacture.

Paul

Bachman, who got the first batch of Radtke's initialized balls,

pointed out the utilitarian value of that feature. He said,

"It's a silicone ball world out there now. With everyone having

a set, you can keep track of your own in a crowded gym when your

initials are right there in the ball."

While

he doesn't exactly resent the fact that Dube and Smith have become

the mass marketers of the product he invented, Radtke follows a code

of ethics that takes the others to task for him. He said, "I

got permission to put the diminishing golf ball on the market after

its original inventor, Laurie Ireland, died. I didn't have to get

permission, but I do everything as ethically as possible. A silver

extraction coin I make was originated by a dentist, Doc Zola. When a

guy told me he wanted one and Doc wasn't making them anymore, I made

one for him. But first I showed it to Doc and asked him if I could

make them. He said I could, and I made it better than he did.

"Let's

just put it this way, if I knew someone was making silicone juggling

balls, I wouldn't have made them, too. I'm not resentful, but

sometimes I feel hurt. But they're in business to make money and I

suppose that's what they do. Fortunately I don't have to earn my

living doing it."

He

said he never even considered trying to patent a silicone ball

because a friend in the magic business called patents "an

invitation to a law suit," and not worth the trouble unless the

product had a potential for huge sales.

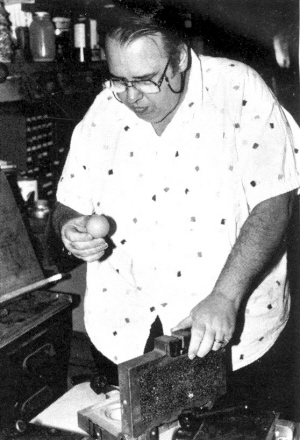

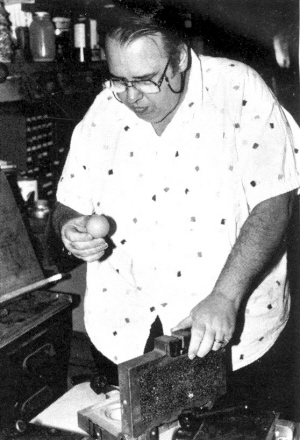

So,

under the business name of "The House of Fakini," he remains

as a smalltime producer of silicone juggling balls and a few other

magic props. He says the balls are only 10 percent of his small business,

that the majority is multiplying golf balls, billiard balls and

flowered items. He performs magic occasionally around Toledo. His

performing name, "Fakini, the Fat Fabulous Fascinator," is

to make sure no one is surprised at what they have hired when he shows

up for a performance at 340 pounds - after losing 70!

All

three manufacturers say that despite

their high price, silicone balls are not a big profit maker. The raw

material is expensive, they're labor intensive, and you can only make

a few at a time. Radtke says his chief reward for his groundbreaking

effort has been new friends in the juggling community. "I really

enjoy talking to jugglers, and have met a lot of them by making these

balls," he said.

0 (If

you 're interested in finding out more about Radtke's silicone balls,

write: Frank Radtke; Toledo, OH.) |

|

|